There is 9 screws:

- 5 are used to retain wood front panel on metal panel. These ones are short.

- 4 are used to retain radio chassis in cabinet. These ones are long.

So, the 4 longer screws and only one short screw are missing.

We must therefore find these screws ...

The problem is that these screws have a round head of 10 mm in diameter and are made of brass.

So I decided to refabricate them.

The principle is simple: solder a round head on a normal screw.

There I was lucky: indeed, the original screws had a diameter of 5/32 ", very close to 4 mm.

On the other hand, the thread is 1/32 "(very close to 0.8mm), while the european ISO M4 screws have a 4 mm diameter and a 0.7mm thread.

In other words, screw 4mm must enter virtually into the tapped brackets, which are pieces of metal about 2 mm thickness; with the difference between the two thread, the screw sould not be blocked.

Indeed, we can screw a screw M4 virtually the length of support.

So it needs to use a M4 tap into the brackets so that the screws drive well:

I take this opportunity also to tap the 5° hole on the front:

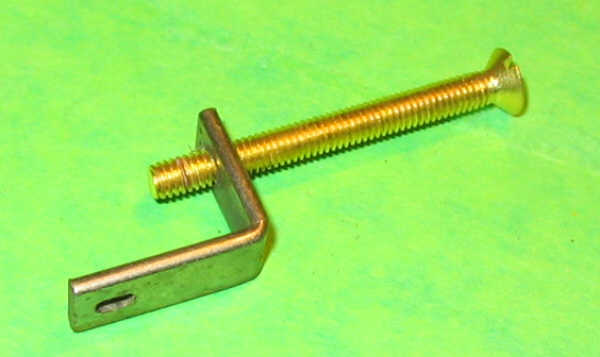

Here is the equipment to make theese screws ...

Brass screw diameter 4mm, at least 30mm length, and nails used for decoration with head 10mm and indifferent length.

We have to start by removing the nail of the head

Then solder the head of the screw in the head of the nail, put enough soldering and testing perpendicularity between head and screw.

Then, it is necessary to make the strait of the head with diamond disc:

Where is the new screw?

Just to finish cut off the screws to the right length:

4 screws with 27 mm

1 screws with 14 mm (head excluded)